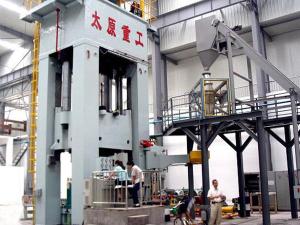

The open die forging presses offered by our company have many types. Sorted by structure, the presses have double-column oblique type and four-column type. The open die forging press also has two transmission ways, hydraulic pressure and oil pressure. A wide application has been found in the open die forging manufacture of rolls, shafts, spindles with different shapes, like cylinder, disc, ring and more.

| Name | Nominal Force | Occupation area (L×W) (m) | Height (m) | Power (KW) | Working speed (Max. pressure) | Manipulator |

| 35MN hydraulic forging press | 35MN | 16.6×18.6 | 13 | 3000 | 30mm /s | 40T |

| Name | Nominal Force | Occupation area (L×W) (m) | Height (m) | Power (KW) | Working speed (Max. pressure) | Manipulator |

| 45MN hydraulic forging press | 45MN | 18.5×20.5 | 13.5 | 4000 | 30mm /s | 40T |

| Name | Nominal Force | Occupation area (L×W) (m) | Height (m) | Power (KW) | Working speed (Max. pressure) | Manipulator |

| 63MN hydraulic forging press | 63MN | 23.6×23 | 14.5 | 5500 | 30mm /s | 60T |

| Name | Nominal Force | Occupation area (L×W) (m) | Height (m) | Power (KW) | Working speed (Max. pressure) | Manipulator |

| 80MN hydraulic forging press | 80MN | 26.9×24.6 | 15.6 | 7800 | 30mm /s | 100T |

| Name | Nominal Force | Occupation area (L×W) (m) | Height (m) | Power (KW) | Working speed (Max. pressure) | Manipulator |

| 125MN hydraulic forging press | 125MN | 33.5×26.9 | 19 | 11100 | 30mm /s | 180T |

-

-

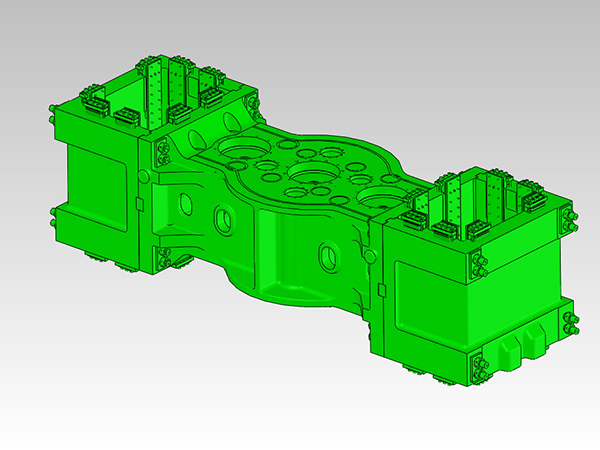

1. Strong Body

With a double-column prestressed combination frame structure and multi-bar pretension technology, realizing improvement on the machine's rigidity, stability, anti-fatigue capacity, service life and one time higher eccentric forging range.

-

2. Plunger -Type Cylinder

By using an articulated hinge rod, the plunger type cylinder reduces the rigid constraint to the movable beam and the horizontal force to the sealing joint of guide sleeve, posed by the main plunger, thus enhancing the sealing performance and prolonging the lifespan of guide sleeve.3. Totally-enclosed Structure

The excellent sealing performance contributes to remarkable decrease in deformation of machine frame as well as in the clearance between column and movable beam. What's more, by adjusting the movable beam, the column and the guide plate can fit closely.

-

-

4. High Precision and High Utility

With the application of pressure and position close-loop control system, the hydraulic forging press achieves a precise control over speed and position and reduces the processing times, thereby cutting the energy consumption and improving the forging precision and material utility.5. Flexible Processing Mode

Designed with flexible pressure and speed options, the hydraulic forging press can produce forgings at different speed and pressure, with regard to different manufacture techniques. The maximum working speed is up to 160mm/s.6. Slight Error

We especially designed large-inertia loading and high-precision position control system, enabling the thickness error of forging is less than ±1mm.7. In-House Developed Manipulator

The rail-type manipulator provides quick response, high precision and non-backlash reverse transmission, leading to a better forging quality.8. High Efficiency

The press matches well with versatile molds and forging equipment, realizing a high level of automation and mechanization. That's why the hydraulic forging press is known for its capacity in cutting auxiliary time and energy consumption, increasing production efficiency and load rate.

Open Die Forging Press

Hydraulic Rail Forging Press

Hot Die Forging Press