- Home

- Equipment Capability

- Design and Development

Founded in 1950s, the R&D team is responsible for the design, research and improvement of new products. This team totally has 410 employees, among which, 31 are professor-level senior engineers and 192 are senior engineers. Not only that, the team has a uniform distribution of talents in machinery, hydraulic and electricity field, ensuring no professional shortage in any field. The technology center is also a gathering place of post doctors, further guaranteeing our research and development capacity.

-

- Steelmaking Equipment

The medium and large-scale casting system includes 15t electric arc furnaces, 25t LF(ladle furnaces)+ VOD (vacuum oxygen decarburization) furnaces, 30t electric furnaces, two 40t LF (ladle furnace) and (VD) vacuum degassing furnace, medium-scale resin-bonded sand production line, large-scale sodium silicate processing line and 7 sets of large-scale thermal processing furnaces. These efficient machines can provide 230t molten refined steel at a time, able to produce various casting components of less than 180t.

-

80t electric furnace

80t electric furnace -

120t ladle refining furnace

120t ladle refining furnace -

40t/h sand mixer

40t/h sand mixer -

120t LF+VD ladle refining furnace

120t LF+VD ladle refining furnace

-

- Casting Equipment

Steel cast parts manufactured by our company mainly are large-scale rolling mill stand, large-scale rolling mill components, etc. After ceaseless experiments and practices for three years, we managed to produce front platens and rear platens for 225MN and 235MN horizontal single-action extrusion press, as well as upper beams, lower beams, moving beam, columns and other large cast parts for 350MN multi-direction vertical press. Plus, the column usually has a net weight of 480t and a size of 4300×7500×11500 mm.

-

10,000-ton casting system

10,000-ton casting system -

350MN multi-direction vertical press

350MN multi-direction vertical press -

600T lifting beam

600T lifting beam

-

- Forging Equipment

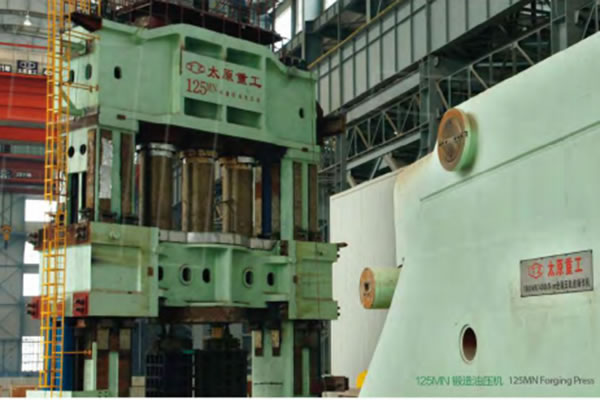

These processing systems are able to forge 240t workpieces at a time, including power station forged parts (generator rotor, steam turbine rotor, vane wheel), marine forgings (intermediate shaft, propeller shaft, rudder shaft) and Cr3 series large-scale back-up rolls and other types of forgings. In recent three years, our firm successfully developed and produced 225MN horizontal single-action aluminum extrusion press, 235MN horizontal single-action aluminum extrusion press and cylinders and plungers for 350MN multi-direction vertical press.

-

125MN double-column forging press

125MN double-column forging press -

45MN open die forging press

45MN open die forging press -

Thermal treatment furnace, 6.5m×25m

Thermal treatment furnace, 6.5m×25m -

225MN extrusion press

225MN extrusion press

-

- Heat Treat Equipment

Taiyuan Heavy Industry has great strength in heat treatment. Our company is equipped with various shaft-type heat treatment furnaces and trolley-type heat treatment furnaces. Among them, electric heating heat treatment furnace has the temperature uniformity within ±5℃. We can undertake heat treatment of machinery products, accessories for mines and factories, big forgings, forgings for power stations, pressure vessels and military products. We can also meet the process requirements for normalizing, annealing,hardening and tempering, quenching, industry-frequency, medium-frequency, superhigh-frequency and high frequency case induction heat treatment and chemical heat treatment such as carburizing and ionic nitriding of different products.

Heat treatment furnace group

Heat treatment furnace group

6.5x25m Heat treatment furnace

6.5x25m Heat treatment furnace

φ4x2m Carburizing furnace

φ4x2m Carburizing furnace

Industrial frequency machine tools

Industrial frequency machine tools

- Machining Equipment

The North Zone is outfitted with these following machines, 2 sets of Φ200 floor-type NC boring and milling machine, 1 set of 4×12 m bridge-type NC milling machine, 1 set of 12m horizontal-type NC grinding machine, 1 set of Φ800 honing machine, 1 set of 3×4m NC gantry surface grinder and 1 set of Z33100×70 radial drilling machine.

-

Equipment in North Zone

Equipment in North Zone -

Equipment in North Zone

Equipment in North Zone -

Equipment in Middle Zone

Equipment in Middle Zone -

Assembly zone

Assembly zone

-

- Quality Assurance system

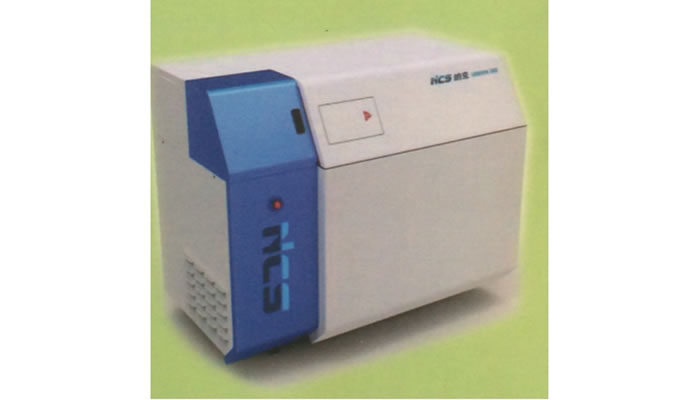

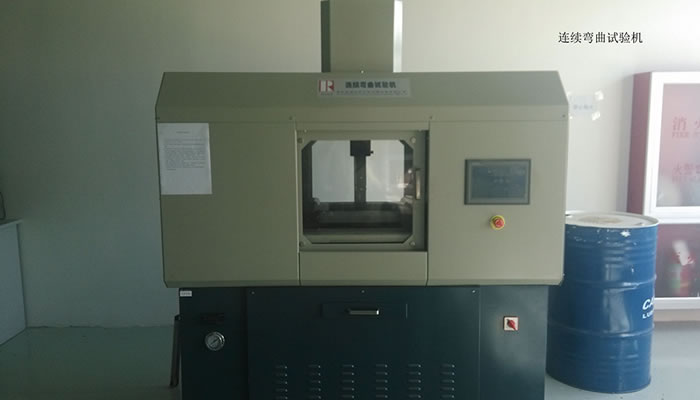

To date, we have brought in more than 200 sets of professional testing devices, 9 sets of measurement standard devices and other 20 sets of state-of-the-art testing instruments imported from Germany, Japan, the U.S., Britain and Belgium, etc.

-

Labspark 1000-type spectroscope

Labspark 1000-type spectroscope -

Brinell's hardness tester

Brinell's hardness tester -

Vickers hardness tester

Vickers hardness tester -

Continuous bending tester

Continuous bending tester

-