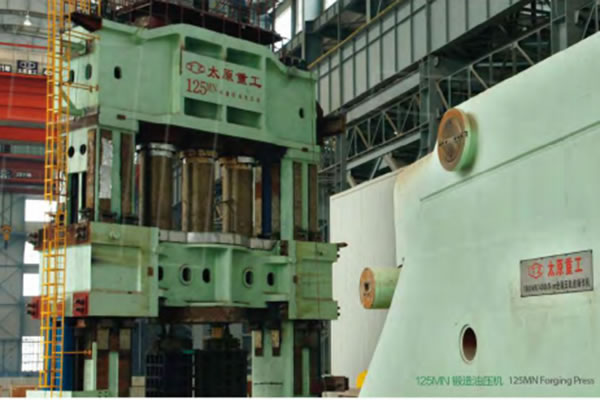

Our company owns many in-house developed forging machines and combined machine sets, including 125MN double-cylinder forging press + 180T forging manipulator + 450T forging crane, 45MN open die forging press + 40T forging manipulator + 80T forging crane and many thermal treatment furnaces. These processing systems are able to forge 240t workpieces at a time, including power station forged parts (generator rotor, steam turbine rotor, vane wheel), marine forgings (intermediate shaft, propeller shaft, rudder shaft) and Cr3 series large-scale back-up rolls and other types of forgings. In recent three years, our firm successfully developed and produced 225MN horizontal single-action aluminum extrusion press, 235MN horizontal single-action aluminum extrusion press and cylinders and plungers for 350MN multi-direction vertical press.

- Home

- Equipment Capability

- Forging Equipment

Forging Equipment